The luxury watch industry has long been synonymous with exceptional craftsmanship, precision, and timeless design. Switzerland, known for producing some of the world’s most prestigious watch brands, continues to be at the forefront of watchmaking excellence.

While traditional techniques remain highly valued, advancements in technology have revolutionized the industry. One such innovation is Swiss CNC machining, which allows manufacturers to combine their time-honored methods with cutting-edge precision.

In this article, we explore how Swiss machining service enhances luxury watchmaking, enabling the production of intricate components, maintaining high-quality standards, and supporting the enduring legacy of Swiss craftsmanship.

The Art of Swiss Watchmaking

Swiss watches are revered for their impeccable quality and intricacy. For centuries, watchmakers in Switzerland have relied on manual techniques to craft every part of a timepiece, from the casing to the movement.

This artisanal approach is complemented by meticulous design, as Swiss luxury watches are not just tools for telling time—they are works of art and symbols of status. As demand for luxury watches has grown, so has the need to produce components with even greater precision, often in smaller sizes and tighter tolerances. This is where Swiss CNC machining plays a crucial role.

What is Swiss CNC Machining?

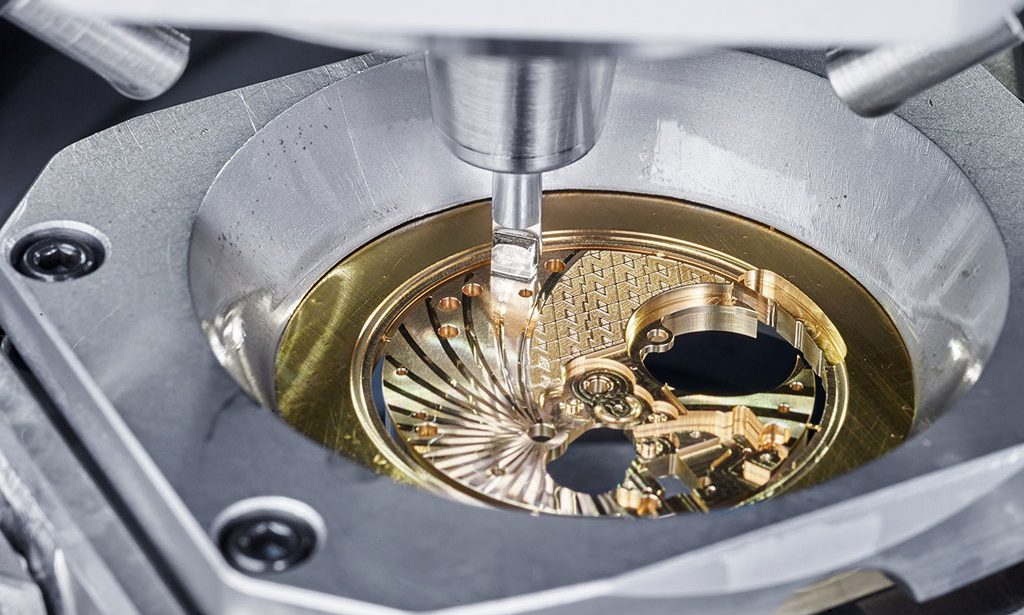

Swiss CNC (Computer Numerical Control) machining is an advanced method that allows for the automated and highly accurate production of complex parts. In this process, cutting tools and high-speed spindles are controlled via pre-programmed computer software to create highly detailed and intricate components, with minimal manual intervention.

A key feature of Swiss CNC machining is the use of a sliding headstock, which feeds the material through a guide bushing as it is machined. This continuous support system results in improved stability and enables the production of smaller, more precise components—ideal for luxury watchmaking.

Precision in Watch Components

Luxury watch components are characterized by their minute size and the need for extreme precision. From delicate gears and screws to minuscule springs and jewel mounts, every part must meet strict tolerances to ensure the timepiece functions flawlessly. Swiss CNC machining is essential in achieving this level of accuracy, as it can consistently produce parts within microns of the required specifications.

For example, the movement inside a Swiss luxury watch—often referred to as the “heart” of the watch—is composed of many intricately machined parts that must work in perfect harmony. Swiss CNC machines can create these components with incredible detail and exactitude, minimizing errors and ensuring the highest quality. This precision also extends to the outer case, dial, and other aesthetic elements, where flawless craftsmanship is key to maintaining the watch’s luxurious appeal.

Maintaining Tradition with Technology

While Swiss CNC machining offers unmatched precision, it does not replace the artistry and tradition of Swiss watchmaking. Instead, it enhances these qualities by ensuring that the high standards of craftsmanship are upheld. Watchmakers still design and oversee the process, ensuring that the components reflect their vision and meet their exacting standards.

Many luxury watch brands employ a hybrid approach, using CNC machining for the precision parts and then finishing them by hand. This combination allows for the creation of reliable, highly functional timepieces without sacrificing the traditional aesthetic that defines Swiss luxury watches.

For example, after the CNC machining process, craftsmen may polish the case, hand-engrave intricate designs, and assemble the movement by hand, ensuring that each watch carries the personal touch of the maker while benefiting from the efficiency and precision of CNC technology.

Benefits of Swiss CNC Machining in Luxury Watches

The incorporation of Swiss CNC machining in luxury watch production offers several key benefits:

- Enhanced Precision: Swiss CNC machining can achieve tighter tolerances and more accurate measurements than manual methods, ensuring that each watch component functions seamlessly.

- Improved Efficiency: Automation allows for faster production of complex parts, enabling manufacturers to meet increasing demand without compromising on quality.

- Complexity and Intricacy: With CNC machining, manufacturers can produce more intricate and detailed parts, opening up new possibilities for innovative watch designs.

- Consistency: CNC machines produce components with consistent quality, reducing the risk of errors and ensuring that every watch meets the high standards expected of Swiss luxury watches.

- Customization: CNC machining makes it easier to customize individual components, allowing luxury watchmakers to offer personalized options to their discerning clientele.

The Future of Swiss Watchmaking

As Swiss watchmakers continue to embrace advanced technology, Swiss CNC machining will play an increasingly important role in the future of luxury watch production. The ability to produce precise, intricate components quickly and consistently ensures that the Swiss watch industry can meet the demands of a global market while preserving its rich heritage.

By combining tradition with technology, Swiss CNC machining not only enhances the quality and precision of luxury watches but also ensures that the artistry and craftsmanship of Swiss watchmakers continue to thrive in a modern, competitive landscape.

Conclusion

Swiss CNC machining has revolutionized luxury watchmaking, offering unparalleled precision and efficiency without losing sight of traditional craftsmanship. It allows watchmakers to meet the evolving demands of the market while maintaining the quality, beauty, and exclusivity that Swiss luxury watches are known for. As the industry continues to innovate, the fusion of time-honored techniques with modern technology will ensure that Swiss watches remain a symbol of excellence for generations to come.